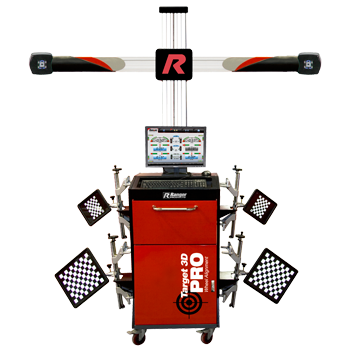

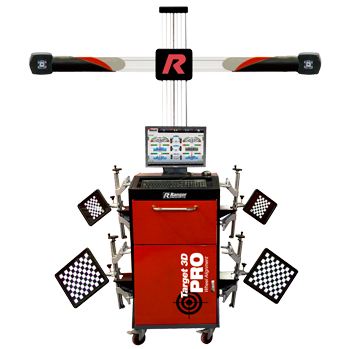

With minimal investment and reduced training the Ranger Target 3DPro aligner expands your service potential and sends more profit to your bottom line. ProSpec® software includes the essential software tools to perform fast, accurate alignments with factory results. Ease of use, accurate and consistent results, and informative feedback that assists the technician in diagnosing problems all add up to customer satisfaction and improved shop efficiency. All alignment steps from start-to-finish are clearly shown with vibrant animation and graphics providing a faster, more profitable and far easier to understand alignment procedure. Simplistic read results enable you to also identify potential problem areas specifically related to suspension components.

ProSpec® software was designed to give your wheel alignment service the best possible efficiency. It gives you the option of selecting the most effective measuring routines before starting wheel alignment procedures. Standard option for a program-guided routine with initial and final measurements - rapid procedure for measurements without caster steering angle and/or run-out compensation - or free measurement for checking individual values as required.

The Target 3DPro aligner combined with ProSpec® results-driven software guarantees:

• Increase in bottom line revenue

• 30 percent average increase in read-rate accuracy

• Fewer costly re-reads and investigations

• Decline in come-backs and customer complaints

ProSpec® Alignment Software

• Specially designed for ease of use, speed and helpful technician feedback

• Choose from 3 individual alignment procedures:

o Standard start-to-finish computer guided program

o Quick readings without caster steering angle and/or run-out compensation

o Free range measuring for checking individual readings as required

Screen displays include:

o Front and rear axle readings

o Front and rear toe (also "super toe" > toe out on turns)

o Front and rear camber (-15º to +15º)

o Front caster (-28º to +28º)

o Individual caster, camber and toe

o Front and rear setback, SAI and thrust angle, included angle

o Elevated 3 Point or rolling run-out compensation

o Elevated adjustments

o Individual zoom readings allows operators to clearly see screen and software function from any wheel position

o Customer database with customer notes and comments

o Before and after adjustment readings

o Visual vehicle adjustment help

o ProSpec® software is available in multiple languages. Check for current language availability.

o Optional yearly specification and software updates are PC network

available or by simply installing a new program cartridge.

o Help Menu

User-Friendly Time-Saving Features

• Self balancing, variable height camera lift system is built with precision bearing slides for easy adjustment

• Commercial-grade cameras are designed with full frame optical lenses that ensure accuracy and stability

• Interactive software provides demonstration screens that assist the

technician to easily proceed systematically through the adjustment

process

• Rugged checkerboard shockproof wheel targets are drop-tested for

worry-free handling and are built with anti corrosion components capable

of withstanding harsh working environments.

• German engineered ProSpec® software has been designed to be compatible with Windows 7 and capable of future upgrades.

• In less than 2-minutes, technicians can complete total vehicle

set-up (including run-out compensation) and obtain full geometry

alignment readings.

• Exclusive One-Touch enhanced software interface results in increased productivity.

• A web based application that can be accessed from iPhone, iPod

touch and iPad users to enjoy full wireless remote operation.

• A reduction in the number of vulnerable electric components results

in reduced downtime, lower operating costs and a longer service life

cycle of the equipment.

• Superior screen graphics with vibrant animation and displays deliver easy to understand visuals and instruction.

• Alignment functions and measurements are controlled via the wheel sensors, mouse and/or keyboard.

• Self-explanatory graphic user surface provides simple understanding

• Compatible with low ride-height vehicles or those with ground-effects

• Self-centering wheel-clamp adaptors cover an extended range of vehicles

• Cordless design remove hassle of connecting cables

• Technician has the option to customize alignment units of measure, accuracy, language, etc.

• Technician has a choice of rolling or lifted run-out modes

• Features self-diagnostic help screen and system information

• Continuous checking ensures accurate toe measurements

• On-screen display indicates if sensor leveling is required

• Vehicle adjustment illustrations and multiple adjustment bar graphs

• Adjustment illustrations provide illustrated diagrams and instructional information of recommended OEM adjustment methods

• Valuable customer information can be conveniently stored in the

database allowing shop personnel to quickly reference previous alignment

work orders

• Convenient “spoiler setting” adjustments on the wheel-clamps for

accommodating blocked front or rear line-of-sight of the sensors and

provides accurate toe measurements

• Before and after measurements can be printed in full-color to explain service and record work performed

NOT FOR SALE IN USA OR CANADA

• Full-sized, sloped keyboard for easy use. Provides user-friendly control of all alignment procedures.

• (♠) Dell® OptiPlex® PC(♣) with powerful Intel® Core2 Duo 1.60 Ghz processor provides high-powered processing with low-power consumption.

• Genuine Windows® 7 Operating System

• Intel® Graphics Media Accelerator

• 8 USB Ports (2 front, 4 back, 2 internal)

• (♠) Dell 17” E178FP Flat Panel LCD Monitor (♣) (19” and 21” optional) designed for complete comfort and convenience with 1280x1024 pixels resolution for sharp and brilliant images of text and graphics. Offers wide viewing angle of 160° horizontal and vertical

• (1) Mobile rolling cabinet with integrated storage.

• (4) 13”-25” wheel clamps

• (1) Target 3DPro variable height camera lift

• (1) Steering wheel lock

• (1) Brake pedal depressor

• (1) Computer mouse

• (1) Console keyboard

• (♠) Dell V313 All-in-One Printer

• Current year domestic and foreign car vehicle specifications

(♠) Comparable unit will be supplied if unavailable at time of purchase

(♣) All supported by round-the clock Dell Technical Support

Optional

• Sensor calibration fixture

Equipment Specifications

Power Requirements: 115V / 1Ph, 50/60 Hz / 8 amp - 230V / 1Ph, 50/60 Hz / 8 amp

NOT FOR SALE IN USA OR CANADA

Featured accessories for the Target 3DPro™ Imaging Wheel Aligner

Breve Información

| Power Requirements: | 115V / 1Ph, 50/60 Hz / 8 amp - 230V / 1Ph, 50/60 Hz |

| Wheel Capacity: | 25" |